Left wing

Inspection ports

I spent several hours match drilling the holes for the inspection frames to the wing skin, then deburred, dimpled and riveted them into place. A couple of the covers needed minor trimming to fit properly.

Aileron cable hole

I measured the hole position from the right wing and transposed it to the left wing, checked that it longed up correctly, before drilling and Dremeling the hole to a slightly elongated shape. The attachment on the aileron cable fits through the hole ok,

Flap Linkage

I also measured the position of the flap arm when retracted both for the angle, and also the in/out location so the cable will line up correctly when fitted. Then I drilled slightly under size for an AN3 bolt, and reamed to size for a good fit.

Landing light

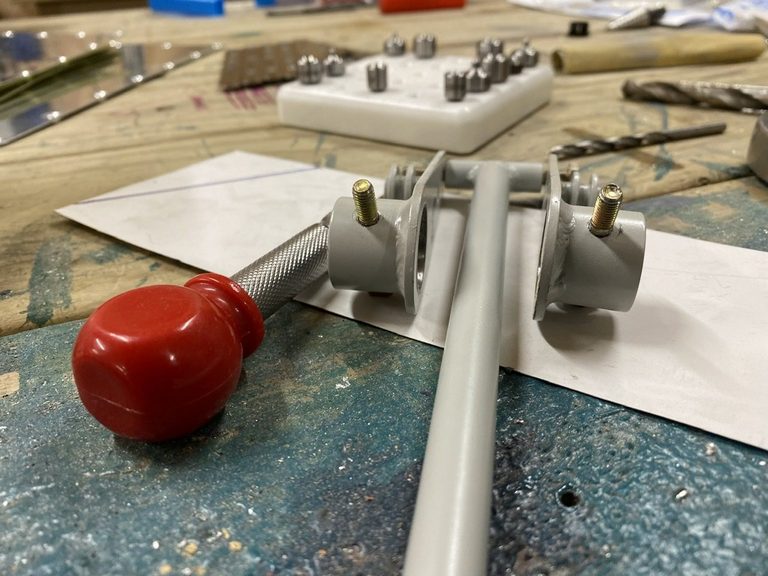

I'm going to be installing an LED light from Vans with the installation kit. It came with a template for an RV 14, which I've traced onto the wing on the outboard bay. I'll fabricate a baffle to run vertically between the top and bottom skins to mount the hardware to and rivet it in place. I plan to shape a piece of acrylic around the leading edge then cut it it to shape and drill it for the lens, and attach it using nutplates.

This post is from Neville's Bearhawk